ppt of cement menufecturing by dry process

Хөнан Лимин хүнд даацын машин механизм, шинжлэх ухаан техникийн ХК-д тавтай морилно уу. Та санал хүсэлтээ үлдээх эсвэл бизнесийн журмаар бидэнтэй холбогдож болно. Манай борлуулалтын менежер таньтай холбогдох болно.

(PDF) Cement Manufacturing - ResearchGate

2015year12month9day Table 1. Raw materials are used to produce the main cement elements (Mohsen, 2015) • Quarry The process of obtaining raw

узнать больше

Cement Manufacturing - Institute for Transportation

2018year8month3day Cement Manufacturing Process. CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss ... Generalized Diagram of a Long Dry Process Kiln Burner Kiln hood Clinker cooler Clinker

узнать больше

Cement Manufacturing—Technology, Practice, and

2021year11month17day There are four main types of processes used in cement manufacture: Dry Process, Semi-dry Process, Semi-wet Process, and the Wet process. In all these

узнать больше

Cement Production - an overview ScienceDirect Topics

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity. Cement production accounts

узнать больше

sbm/sbm ppt of cement menufecturing by dry process.md at

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

узнать больше

Chapter 4 Cement Manufacturing and Process Control

2019year8month26day The most common way to manufacture Portland cement is through a dry process. The first step is to quarry the principal raw materials, mainly limestone, clay,

узнать больше

(PDF) THE CEMENT MANUFACTURING PROCESS

They are mixed either dry (dry mixing) or by water (wet mixing). 3) Prepared raw mix is fed into the rotary kiln. 4) As the materials pass through the kiln their temperature is rised

узнать больше

1 Manufacturing Process of Cement - coursecontent

2020year8month13day There are three processes by which cement is being manufactured: A) WET Process. B) DRY Process. 3) CEMENT – MANUFACTURING . STEP-1 Stone is

узнать больше

Dry Process Of Cement Manufacturing - Dry

Small Pollution. The new dry-process of cement manufacturing technology makes good use of the limestone resources discarded in the traditional mining method and applies the pre decomposition technology,

узнать больше

of cement menufecturing by dry process

Dry Process Of Cement civilenggnotes. 2018-8-24 Dry process. These are two different processes of manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like substance.Both the processes are in use and have their own advantages and

узнать больше

2 Process Of Manufacture Of Cement - Wet

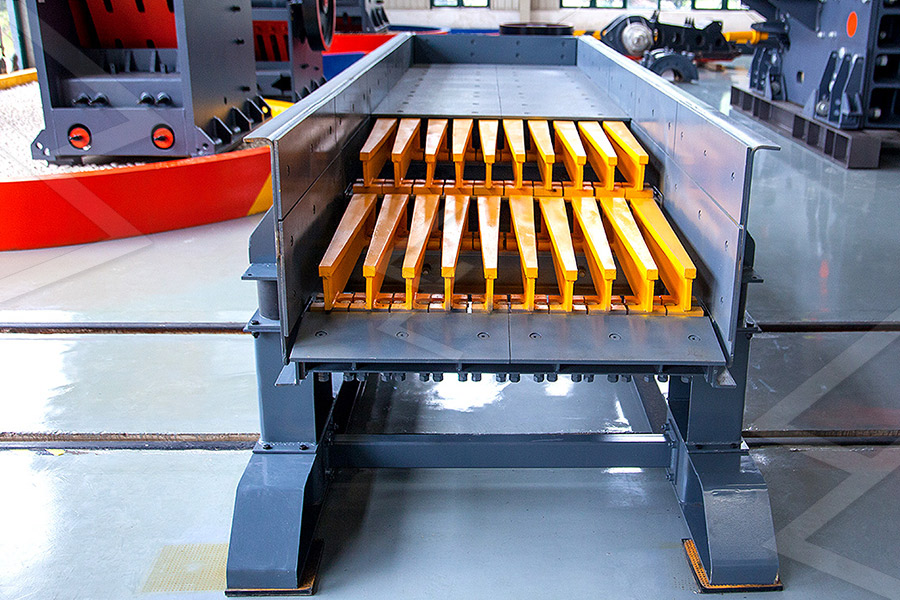

Wet process. Dry Process of Manufacture of Cement: Crushing of limestone and clay in crushers and stored in silos. Grinding of crushed materials and storing in hoppers. Mixing of materials by compressed air in the right

узнать больше

Total Quality Control for Manufacturing of Plastic Woven

2021year8month10day management. In this chapter the rejection ratio of plastic weaving process department was analyzed statistically using DMAIC methodology and suggestions for quality improvement will be made to the department. DMAIC – Define stage Define the process Before the process can be investigated, all circumstances have to be defined.

узнать больше

ppt of cement menufecturing by dry process - jaworzielen

What Are the Differences Between the Wet and Dry Processes manufacturing of cement by wet and dry process ppt. The wet process of cement manufacturing involves adding water to finely crushed raw material such as limestone clay or iron ore in a proportion of 35 to 50 percent water to 50 to 65 percent raw material to make a slurry that is fed ...

узнать больше

ppt on cement manufacturing

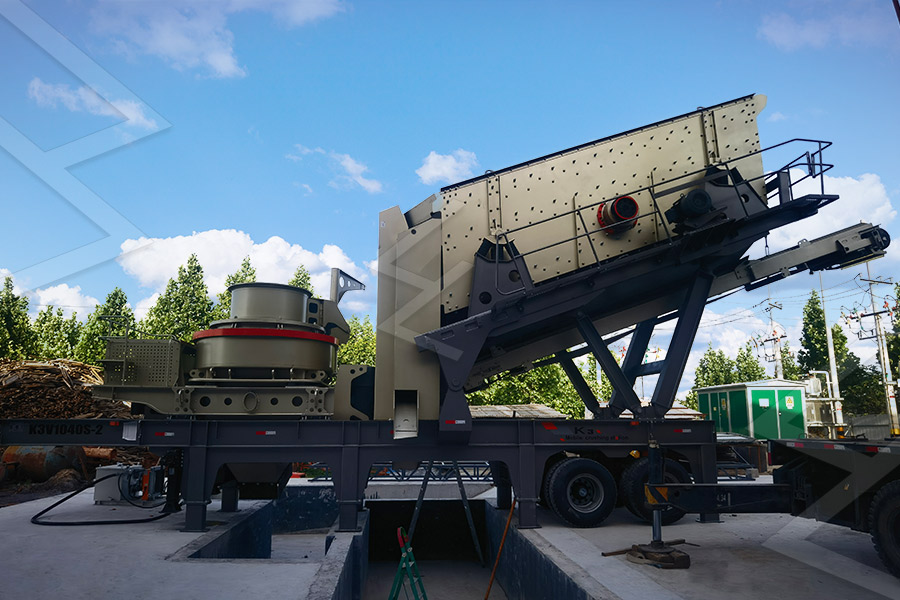

As the second crushing process, CS High-Efficiency Cone Crusher can process river stone, granite, basalt and ironstone for medium crushing. This machine takes advantages of safety and easy maintenance, and its overload protection device can make the production stable and steady. ... ppt on cement manufacturing

узнать больше

Cement Manufacturing—Technology, Practice, and

2021year11month17day The manufacturing of cement clinker was initially based on the “wet” process, but the “dry” process is today the state of the art. The “semi-wet” and “semi-dry” processes were intermediate. 4.1 The Dry Process. The raw meal is prepared by drying and grinding in ball mills or vertical roller mills.

узнать больше

Blended Cement - an overview ScienceDirect Topics

Figure 5.3 shows an example of the changes in CO 2 emissions from the process of producing blended cement. This example the shows effect of the substitution of clinker by granulated slag for a CEM II/B-S 32, 5 with 35% granulated slag. It can be seen that, on the one hand, there are savings in CO 2 emissions from fuel consumption, from electricity

узнать больше

of cement menufecturing by dry process

cement dry manufacturing process . Dry Process Of Cement ManufacturingDry Process Of 26/11/2019 Dry process cement production kiln is the typical kiln type during the end of the 18th century and the beginning of the 19th century It is a big step for haft kiln Because of its less than 1 water content dust raw materials it reduces the most needed heat for

узнать больше

sbm/sbm cement industry ppt presentation beltconveyers

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

узнать больше

m/sbm cement dry process technology.md at main

Contribute to legaojm/m development by creating an account on GitHub.

узнать больше

Calcium Carbonate Manufacturing Process and Equipment

2 天之前 The Calcium Carbonate Manufacturing Process. Natural mineral sources are necessary to make commercially usable calcium carbonate. Manufacturing processes are used to improve specific properties and reduce the size of particles within the material. Calcium carbonate is mined from open pits or underground, then drilled, blasted, and

узнать больше

manufacturing of cement by dry process ppt

Cement Manufacturing Process And Quality Control1. 2012-12-17 41 Semi Dry Process In this process all raw materials are ground in dry state and the resultant powder is pelletized into small nodules by means of 10 15 % of water addition, then the nodules are fed into kiln.

узнать больше

Manufacturing Of Cement: Stages To Follow - Housing

2023year4month5day The production of cement involves six crucial stages in its manufacturing process that are: 1. Raw material extraction. To produce cement, various raw materials are required, including limestone (which is rich in calcium), sand, clay (which contains silicon, aluminium, and iron), fly ash, shale, bauxite, and mill scale.

узнать больше

dry cement plant cement porland 90 m3/h cement qtf4 24

2023year4month12day Dry Process Cement Plant Ppt Flowchart YouTube. Aug 08, 2018 It is a dry process plant Ppt Of Cement Menufecturing By Dry Process djzfvcBlock Diagram Of Power Plants Or Ppt; manufacture of portland cement wet process and dry process ppt, [Chat Online] 116 Portland Cement Manufacturing - Difference between Wet and Dry

узнать больше

composition of cement plant - shibang-china

the importance of crusher in a cement industry; ppt of cement menufecturing by dry process; machines used in cement plant; cement mill surge bin; types of crusher plant in cement unit . Home > ShowRoom > composition of cement plant . Analysis of cement, Cement analysis. Traditionally, Cement analysis was carried out using wet-chemical techniques.

узнать больше

ppt of cement menufecturing by dry process-Cement

What are the differences between the wet and dry Cement kiln Wikipedia. What are the differences between the wet and dry processes of a cement manufacturer A The wet process of cement manufacturing involves adding water to finely improvement of kiln efficiency has been the central concern of cement manufacturing technology in a cement

узнать больше

Dry Process Of Cement Manufacturing - Dry Cement AGICO

The new dry-process of cement manufacturing technology makes good use of the limestone resources discarded in the traditional mining method and applies the pre decomposition technology, suspension preheating technology, and multi-channel burner to reuse the recycled and low-quality fuels. Besides, it effectively reduces the emission of NO 2 and ...

узнать больше

Manufacture Of Portland Cement Process Flow chart - civil

2019year11month30day Mixing of raw materials: The processes used for the manufacture of portland cement can be classified as dry and wet. In dry process. The raw materials are first reduced in size of about 25mm in crushers and Crushed material is ground to get fine particles into ball mill or tube mill. Each material after screening is stored in a separate

узнать больше

ppt for cement manufacturing process - ster

Dec 31, 2015 Manufacturing of cement starts at the quarry Stone is first reduced to 5inch size, then to 3/4 inch, and stored Dry process of raw mix preparation Raw mix changes chemically Mar 31, 2015 1 cement ppt 1 Cement: Cement is the mixture of calcareous, siliceous, argillaceous and other substances Cement is used as a binding material in ...

узнать больше

Cement manufacturing process PPT - SlideShare

2016year1month29day 4.Cement production A cement production plant consists of the following three processes. 1. Raw material process 2. Clinker burning process 3. Finish grinding process The raw material process and the clinker burning process are each classified into the wet process and the dry process.

узнать больше

>> Next:самодельное оборудование для измельчения глины

- дробилка щековая для руды

- камнедробилка каньон амфитеатр

- маленький рок мельница камни

- поставщик щековых дробилок

- что такое строительные отходы

- камни карьер дробилки бизнес планы

- шаровая мельница для железа в Индии

- мелкий гравий и песок поставщиков ченнаи

- сравнительные цены мельничных комплексов

- конусные дробилки для продажи NZ

- ленточный конвейер с сушкой

- магнитного для дробилок

- производитель карьер дробилки дробилки

- цены на дробилки роторные

- запасные части для угольной дробилки