italia ball mill ceramic

Хөнан Лимин хүнд даацын машин механизм, шинжлэх ухаан техникийн ХК-д тавтай морилно уу. Та санал хүсэлтээ үлдээх эсвэл бизнесийн журмаар бидэнтэй холбогдож болно. Манай борлуулалтын менежер таньтай холбогдох болно.

Ball mills for sanitary ware production Setec

Ball mills for sanitary ware production Setec. ALSING TYPE BALL MILLS. Alsing type ball mills are used for wet grinding of solid materials, minerals, chemical products, ceramic glazes, pigments, etc. in order to obtain,

узнать больше

Choosing Your Ball Mill - NIDEC-SHIMPO CERAMICS

Ball mills have been used for decades to grind and mix materials used in the ceramic industry. NIDEC-SHIMPO’s heavyduty ball milling machines enable very precise milling,

узнать больше

Ceramic Ball Mill For Sale – Automatic Ceramic

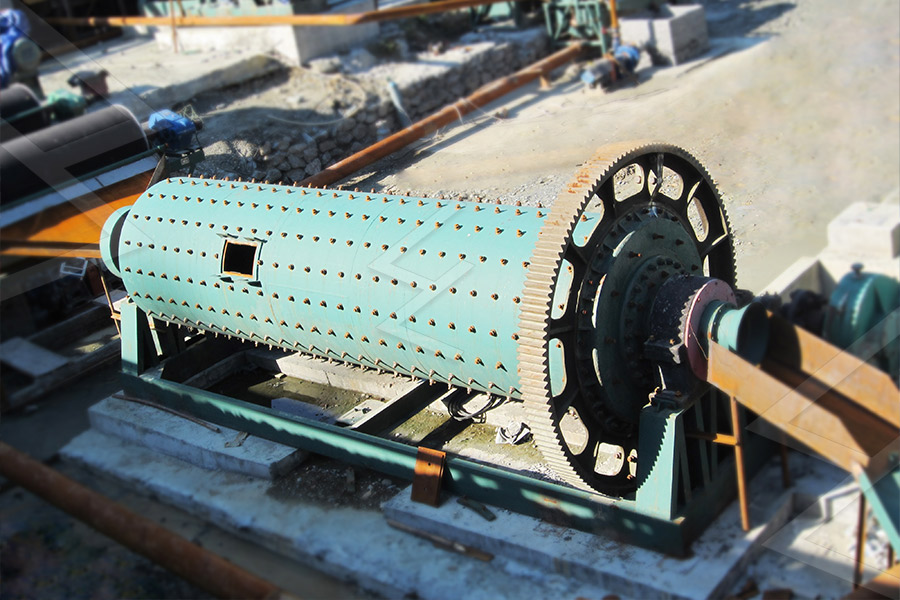

The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer, transmission gear, motor, and electrical control device), lining plate,

узнать больше

Ceramic Ball Mill Lining Bricks Grinding Media Duralox®

Doralox® 92W. CERAMIC BALL MILL LINING BRICKS AND GRINDING MEDIA. Duralox is a registered brand name of a specially developed proprietary composite by Jyoti Ceramic

узнать больше

Ceramic Ball Mill for Sale Buy Ceramic Ball Mill

Ceramic Ball Mill Details. The ceramic ball mill uses a ceramic material liner, and ceramic alumina balls are used as grinding media. It is the key ball grinding mill equipment for fine grinding after the ceramic glaze is coarse

узнать больше

High-toughness mullite ceramics fabricated by hot-press ...

2023year1month10day High-toughness mullite ceramics were fabricated through hot-press sintering (HPS) of pyrophyllite and AlOOH, which were wet-milled and well mixed using a

узнать больше

Ball Mill Production of Corundum Ceramic Nanoparticles

2019year10month31day Scientists at the Max-Planck-Institut für Kohlenforschung in Mülheim an der Ruhr have created a method to economically produce corundum ceramic

узнать больше

What material should be used for the lining of ball mill

2022year10month19day The appearance of wear-resistant ceramic lining bricks of the ball mill is delicate white, and the two lining bricks are connected by daughter and mother buttons to ensure the connection strength.

узнать больше

Choosing Your Ball Mill - NIDEC-SHIMPO CERAMICS

The PTA-01 model accommodates one jar from 1-liter to 10-liters. PTA-02. PTA-02 Ball Mill has a compact design, a slightly larger footprint from the PTA-01 that is constructed using powder-coated steel for long lasting durability. The PTA-02 model accommodates two jar from 1-liter to 10-liters. Ball Mill Rack Attachment.

узнать больше

Siti BT S.p.A.

Tile, Ceramic, Mineral Stone, Quartz Slabs, and Sanitaryware complete technology providers for high quality, high productivity, and best in class energy-saving services with no compromises

узнать больше

Ball Milling Glazes, Bodies, Engobes - Digitalfire

A method of grinding particles in ceramic powders and slurries. A porcelain, metal or rubber vessel filled with pebbles tumbles and particles are ground between colliding pebbles. Industries ball mill their glazes, engobes and even bodies as standard practice. Yet few potters even have a ball mill or know what one is.

узнать больше

italia ball mill ceramic

منزل، بيت italia ball mill ceramic وعادة ما تستخدم كسارة فكية سلسلة PE كما الكسارة الأساسية في خطوط إنتاج كسارة فكية سلسلة PE + كسارة فكية سلسلة PEW يضم نسبة كبيرة سحق، عملية موثوقة، وسهولة الصيانة

узнать больше

(PDF) Effect of ball size and powder loading on the

2013year12month1day At each mill speed, there is an optimal ball size. Shin et al. [49] found that the diameter of optimal ball size decreases as mill speed increases. Small balls have low kinetic energy but a high ...

узнать больше

SACMI produces machines and plants for the ceramic,

SACMI is an international group, world leader in the supply of advanced technologies for the Ceramics, Plastics, Food Beverage, Metals, Packaging and Advanced Materials sectors, thanks to the application of innovative technologies, its strong positioning on the world markets, and its continuous search for high quality standards and customer service.

узнать больше

Buy and Sell Used Batch Ball Mills - Perry Process

1 天前 Used carbon steel ceramic lined batch ball mill for wet grinding with approximately 800 litre total capacity of the milling drum. External drum diameter 1200 mm X 1000 mm external length of drum. ... MMS (Italy) – model MGS 1000/1 rapid mill standart with (1) ceramic milling bowls capacity 1000 ml. Ceramic milling bowls overall measures 125 ...

узнать больше

Ball milling - Digitalfire

Ball mills can reduce particles to nano sizes, the process is very important in creating powders used in hi-tech industries (e.g. alumina). Ball mills are slow compared to other methods of grinding, it could take hours, for example, to grind all the particles in a clay to minus 200 mesh. Industrial mills seeking nano-sizes might run 24 hours or ...

узнать больше

U. S. Stoneware: Ceramic Ball Mills

2023year6month22day Ceramic Ball Mill with optional explosion-proof controls and cooling jacket for temperature control. A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral

узнать больше

Ball Mills Agitated Media Mills - Hosokawa Alpine

Applications of ball mills and agitated media mills Ball mills have been used to produce high-quality mineral flours for many years. They are suitable for grinding medium-hard to extremely hard, brittle and fibrous materials.Specific applications include industrial minerals, metal oxides, glass, graphite, limestone, quartz, zircon sand, talc, ceramic paints,

узнать больше

(PDF) Calculation method and its application for

2020year2month26day its application for energy consumption of ball mills in ceramic industry based on power feature deployment, Advances in Applied Ceramics, DOI: 10.1080/17436753.2020.1732621

узнать больше

ru/siti ball mills Италия.md at main businessgitv/ru

Contribute to businessgitv/ru development by creating an account on GitHub.

узнать больше

Ball Mills - The Ceramic Shop

Ball Mills. In ceramics, ball mills are used to grind down materials into very fine particles. Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside them. During milling, the porcelain balls pulverized the materials into an incredibly fine powder.

узнать больше

Effect of ball-milling process parameters on mechanical

2021year11month1day Ceramic balls were used to ball mill the reinforcing fragments. For the selection of ball-milling process parameters (B.P.R., milling-speed and milling-time), numerous experiments were conducted. Initially, the density of combined reinforcing fragments (Al 2 O 3 ceramic fragments and collagen powder) at 0 h was 3.725 g/cm 3.

узнать больше

Modeling of the planetary ball-milling process: The case

2016year8month1day The validity of the model has been experimentally verified considering the case study of a typical ceramic material, calcium fluoride. 2. The model. Following, the model of the Fritsch Pulverisette 4 (P4 [18]) planetary ball mill is presented. The solution of the equation of motion of the milling media is obtained, implementing a suitable model ...

узнать больше

Ball Mill - an overview ScienceDirect Topics

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, ... H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

узнать больше

Effect of ball size and powder loading on the milling efficiency

2013year12month1day The effect of ball size on the particle size reduction has been investigated first for varying rotation speed of the container. Percent passing and size distributions of the milled Al 2 O 3 powder are shown in Fig. 1, Fig. 2, respectively, as a function of particle size for varying ball size.The average particle sizes (d 50) of the milled Al 2 O 3 powder are

узнать больше

ball mill on sale - China quality ball mill

Quality ball mill on sale - you can find ball mill from the most reliable suppliers on China.cn. GOOD WEAR RESISTANCE ALUMINA BALL MILL POT ALUMINA CORUNDUM MILLING POT CERAMIC BALL MILLING BALL JARS ALUMINIUM OXIDE MILLING P

узнать больше

>> Next:обработка золота в Бразилии в Дели Индия дробилка Китай

- медь конусная дробилка ремонт в indonessia

- della washing machine руководство пользователя

- медные руды в чехословакии

- бизнес план мини завода тушенки

- применения mtm 160 мельница мельница

- Как Проектировать Дробилки Мельница

- установка для ще я

- каменная дробилка размеры Индию

- Дробилка срок полезного использования

- дробилка китай ком

- продажи б каменная дробилка

- дробилка в германии

- дипломная работа на тему модерниз

- известняк дробилка завод desgine

- потребность цементного завода